One of the main questions you will have before starting a steel building project is, "What's this going to cost?" Although every project has unique characteristics, here is the general idea to consider before starting:

Prefab steel buildings typically range from $12 to $20 per square foot.

On average, a fully installed steel building can range from $25 to $ 50 per square foot or more.

Calculate construction cost of a house using the 247pro online estimator.

The Foundation of Profit: Why Accurate Steel Building Cost Estimation Matters

Have you ever wondered how much it would cost to build a steel building from scratch? One thing that always gets tricky is the estimated price. Whether you want to calculate the construction cost of a house, farm storage, or an industrial building, precise financial planning is not just a must; it's a crucial step that can make or break your project before starting.

But no worries, as this guide is here to cut straight to the chase. Here, we provide a practical blueprint for achieving an accurate estimate of steel building costs. Read it, consider it, and take control of your budget with confidence.

In a steel building project, accurate cost estimation isn't just a step in the process; it is how you stay on budget and make a profit.

Understanding the factors that influence the price and predicting risks and delays can help us create a clear vision of what we will face and prevent any financial nightmares. So, accurate steel building cost estimation is far more than just having a number in mind; it is all about strategic prediction, risk management, and securing the project's success.

- Set realistic budgets: create clear and reliable financial plans

- Optimize resources: carefully plan for the costs of materials, labor, and equipment to prevent wasting resources.

- Enhance Profitability: Ensure that your business is strong by ensuring every project works in your favor.

2025 Steel building prices

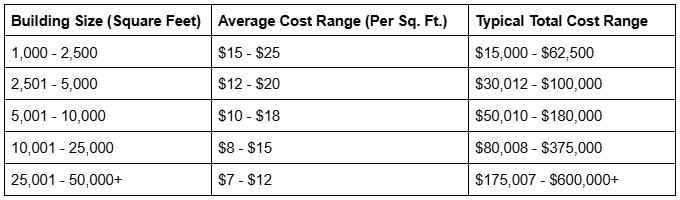

The price can vary depending on several factors; however, the average steel building cost per square foot is listed below:

Use 247pro’s 14-day free trial estimator to calculate the precise cost of your steel building project.

Pre-engineered steel building cost per square foot 2025

A basic kit for a pre-engineered steel building in 2025 typically costs between $15 and $25 per square foot, considering the different factors involved, and this price only includes the materials cost for the structure. The total installed cost, which includes foundation, labor, materials, and other essential components required for the building, can range from $25 to $50 per square foot or higher.

Compared to traditional building methods, a pre-engineered steel building is a more cost-effective option. The prefabricated parts make the building process more straightforward, which can reduce both material waste and construction time. The prices of these buildings can vary based on their intended use and features, even if they're efficient.

How much does it cost to build a metal building?

So, based on the information presented in the table above, the initial steel construction cost can range from $15 to $40 per square foot; however, sometimes bigger projects can cost less. The price depends on many factors, such as location and size, which will be discussed in the following. This average cost mainly includes steel material, fabrication, and delivery. A fully completed project that includes the foundation, installation, and other trends, the final cost of a steel building would go up to $25 to over $100 per square foot.

Deconstructing the Build: Key Cost Components in Steel Structures

Understanding the key components of a construction project is crucial in the steel building cost estimation. This process is multifaceted and influenced by various factors, including materials, labor, design, and transportation costs, among others. To understand this better, let's “deconstruct the build” into its key components.

- Materials: The foundation of any building is its materials. The quality and quantity of steel, as well as other materials such as insulation, roofing, and foundation materials, can help you estimate the overall price. There are some factors regarding the material price:

- Type of Steel: Different types of steel, such as mild steel, stainless steel, and high-strength alloys, carry varying price tags.

- Quantity and Size: Larger buildings naturally cost more as they require more materials. However, sometimes the cost per square foot can decrease due to economies of scale.

- Pre-engineered Metal Building (PEMB) Kits, which include prefabricated components such as beams, columns, and trusses, can significantly reduce the total project cost by minimizing material waste.

- Design and Engineering: Before any steel is cut, the building requires a customized design tailored to the project's specific needs.

- Architectural plans: The more complex the project's geometry or special features are, the more time and budget it will take to design the architectural drawings.

- Structural Calculations: It is crucial to ensure that the building meets local building codes and regulations, which take into account factors such as seismic activity, wind, and snow loads, thereby adding to the complexity and overall cost of the project.

- Site Preparation and Foundation: Before erecting a steel building, the working site needs to be prepared; this includes:

- Soil testing: To determine the proper foundation type for the building, the site’s soil must be tested and a valid report obtained, which will cost between $700 and $1,800, depending on your location. Land clearing and grading to make the site level typically costs between $0.13 and $4 per square foot for clearing and $0.4 to $2 per square foot for grading.

- Foundation Type: After testing the soil at your site, and depending on the size and weight of your building, you will determine the type of foundation to use.

- Concrete slab: This is a very common feature on construction sites and typically costs between $4 and $10 per square foot, depending on its thickness.

- Concrete Piers: For specific designs, you can use concrete piers, which will cost around $500 per pier.

- Labor Costs: From the very beginning, that is, site preparation, to the final step, which includes electrical and plumbing installation, various groups of people will be working on the project. Each will require a different payment. Additionally, labor costs will vary depending on factors such as location, time of year, and availability of skilled workers. In your steel building cost calculator, it is essential to note that labor services typically range from $5 to $15 per square foot for the erection of a steel building.

- Permits and Regulations: Before starting your project, ensure that you have obtained the necessary permits. Again, based on your location and the size of your building, these costs can vary. These include:

- Building permits

- Inspection fees

- Zoning compliance

- Architectural and engineering review fees

- Transportation and Delivery: Transferring the material from the manufacturing plant to your construction site is another important factor to consider when calculating the cost of your metal building. Factors such as the distance from the manufacturing facility and the project site, as well as the size and weight of the material, will impact the price.

How to Calculate Steel Price?

To find out how much your project would cost, follow these two steps: first, find out how much the steel weighs, and then multiply that by the current market price. You need to know how many pounds you're buying before you can figure out how much it will cost. To begin, determine the steel's weight by referring to the blueprints or architectural drawings of your project. The plans should show the sizes and kinds of all the steel parts, such as I-beams, columns, and trusses. A structural engineer or a fabricator can give you a "material takeoff" list that shows how much each piece weighs. This is the best way to get a number since assuming can lead to significant errors in costs.

The next step is to determine the total cost of the weight based on current market rates. Steel prices change frequently, so it's not a fixed number. Contact a local steel supplier for a direct quote to find out the current rate. They can inform you how much it costs per ton or per pound. You can also check industry-specific websites that track steel prices to get a rough idea, but the best way to get a quote for your project is always to ask a supplier directly.

From Back-of-the-Napkin to Bid: Methods and Tools for Steel Cost Estimation

Estimating the cost of a steel building project is a delicate step, and you will need to consider multiple methods. This process begins with initial conceptual sketches and progresses to detailed, formal bids.

Quick Conceptual Estimates:

This estimation occurs when you have only an idea of building a steel structure. This is a quick method for determining feasibility and setting project expectations. There are three methods in this process:

- Historical comparison: Use the data from previous similar projects that share the same size, scope, and function.

- Capacity or Unit Cost Method: For certain building types, such as warehouses, use the cost per unit of capacity

- Square Footage Method: the most common approach for estimation that uses the historical cost data for similar buildings on a per-square-foot basis. This is the simplest metal building price calculator, where you simply multiply the average cost per square foot by your desired building's square footage.

This method is straightforward, and you can complete it independently without assistance from professionals. Simple calculations can be performed using a rule of thumb or a metal building cost calculator to obtain a more precise estimate.

Detailed Estimation

This is the most accurate form of estimating that is performed when the project design is completed. Through detailed architectural and engineering drawings and specifications, you can generate an accurate cost that can form the basis of a firm bid. The methods of such estimation are as follows:

- Material takeoff: measuring every material, from steel beams to a simple bolt, directly from blueprints or online sources.

- Cost Databases: using accurate databases, whether online or printed sources, to get the latest pricing for materials, labor, and equipment.

- Contractor Bids: For specialized trades, request firm bids from different contractors or use the online steel building cost calculator.

Final Bidding: finalizing the Estimate

The final bid is a detailed document that includes all costs and terms. This isn't just a numerical summary; it is a strategic document that helps you. It includes:

- Itemized Cost Breakdown: This includes a detailed list of prices for materials, labor, and equipment.

- Terms and Conditions: These define the payment schedules, project timelines, and any predictions regarding delays and obstacles.

For the final bidding, use 247pro’s steel building cost estimation and project coordinator construction software.

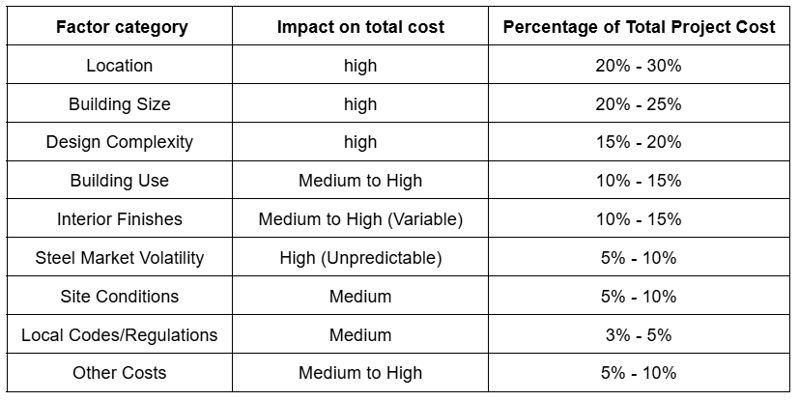

Navigating the Variables: Factors Influencing Steel Building Costs

Suppose you have been in this industry for a while, or even if you are a newcomer to the construction world. In that case, you have surely faced the issue that the price of a steel building can differ significantly from one quote to the next, even for a similar structure.

Several factors can contribute to this inconsistency, including both internal and external influences. Considering these factors is crucial for estimating the cost of a construction project and making informed decisions. So let's answer it once and for all. Why do the prices vary?

Internal Factors

These are the items over which you have some control. Choosing them wisely can have a significant influence on your final price:

- Building size: This is, for sure, a no-brainer. A larger construction means more material, more labor, and ultimately, more expense. But is it always true? Well, not always. Sometimes, larger buildings can take advantage of the cheaper per-square-foot value thanks to economies of scale. Another size-related factor is the "clear span" requirement, which refers to the width of the building without any columns or obstructions. The greater the clear span, the heavier and more expensive the steel will be.

- The complexity of the design: a simple rectangular building will always be cheaper than a multi-level structure with complex interior designs. Every angle and additional feature can add to the final costs.

- Building type: different types of buildings, namely warehouse, agricultural construction, and residential. Manufacturing facilities require a different structure, blueprint, and material, and consequently, a different price.

- Warehouses/Storage: These buildings are generally simpler and cost less per square foot

- Agricultural construction is generally basic and often features open sides. But sometimes, the material should be anti-rust.

- Residential buildings often require more sophisticated interior design and aesthetic considerations, which can drive up the price.

- Manufacturing Facilities: usually require heavier and more robust framing, thus increasing costs

- Framing System: Different structural systems, such as rigid frame, clear span, and multi-span, have varying material needs and labor intensities.

- Number of openings: the more doors and windows, the more complex the project will be, resulting in increased costs for framing and finishing.

External Factors

Some factors are less within your control. So their influence on the price of a building is inevitable.

- Your location: When it comes to construction, location is everything. According to your location and station, labor rates, material transportation expenses, and even local permits and regulatory fees can vary significantly depending on your specific location. For example, building in downtown San Francisco will certainly cost more than building in a rural area of Arizona.

- Global Steel Market Prices: Like many raw materials, the cost of steel can fluctuate due to factors such as international availability, the price of raw materials like iron ore, and energy costs. These factors can make the estimation process somewhat unpredictable.

- Time of the year: Summer is the peak construction season in the USA, which can sometimes lead to higher labor costs. Additionally, building in extreme weather conditions, such as heavy rain and high winds, can cause delays and increase overall project expenses.

- Economic Climate: Tough economic situations, such as inflation and higher interest rates, can significantly impact every aspect of the construction industry, from material costs to labor expenses. Additionally, a booming economy can increase demand for construction and drive up prices.

Here is a table of the factors that can have an impact on the overall price of your project; so next time you are looking at a quote, consider these factors:

Enter your zip code on 247pro’s online estimator to get the accurate cost based on your location and tailored needs.

Beyond the Quote: Project Management & Cost Control in Steel Building Construction

Having a precise steel building cost estimation is just the beginning of the construction process. The main idea to stick to is effectively managing the project to ensure that the actual costs align with the estimated ones. Rigid project management can bridge the gap between pre-construction estimation and the realities of execution.

From Estimation to Execution

Accurate cost estimation is the blueprint for your project's financial and operational success. The breakdown of costs can become the project manager's master guide and inform about:

- Budget baseline

- Resource allocation

- Schedule development

- Risk identification

Cost Control: Keeping the Project on Track

The most effective cost control strategy is to initiate the project, as the majority of damage typically occurs during this stage. Continuing cost control should become a daily discipline. Note that this isn't just about cutting corners, but it's about monitoring everything and making wise decisions. So do as follows:

- Real-time Tracking and Variance Analysis

- Coordination and Communication

- Schedule Management

- Change Order Management:

- Supplier and Contractor Negotiations

- Using online tools and technologies such as 247pro’s project manager

- Regular Financial Reporting

- Productivity Monitoring

By actively monitoring and managing costs, managers can minimize financial risks and ensure the process remains on track.

Steel building project management

Effective management of a steel building project involves several crucial stages. Since careful planning mainly happens during the pre-construction phase, you should never underestimate this stage. It involves setting suitable deadlines, defining the project's scope, and obtaining all necessary permits and legal documentation. A crucial part of this early phase is an accurate site analysis, which involves soil testing and accessibility. Without precise planning, the project is vulnerable to many errors that can lead to delay and budget overrun.

Once construction starts, a project manager's role shifts to supervision and execution. This involves careful material management, labor, and equipment. The manager should ensure that materials are delivered on time, workers are working efficiently, and the project is proceeding according to safety protocols. These measures will help keep the project on track, as well as within the budget and schedule. Identifying any changes to the initial plan early can help prevent delays and cost overruns.

Frequently Asked Questions

How can I get a custom estimate for a metal structure project?

To get an accurate and custom steel building quote for your metal structure project, all you need to do is get the detailed project specifications, including dimensions, building type, such as warehouse, garage, or commercial, all the features you want to add to your project, location, and any special add-ons like doors or insulation. Now you have to put this data on 247pro’s estimator and get the custom estimate. Although this custom estimate is as accurate as possible, you shouldn’t rely just on one quote; get a quote from at least three contractors and compare them.

How much does it cost to build a metal building?

The price of building a metal building typically breaks down into two parts: the basic kit, which costs $15 to $25 per square foot, and the fully installed price, which can be anywhere from $25 to $100 or more per square foot, depending on how complicated it is and what finishes are used.